The demand for products is at an all-time high, and companies everywhere are feeling the pressure to deliver faster, more efficiently, and without compromising quality. One of the silent workers meeting these challenges head-on is the packaging machine.

These technological marvels are transforming production lines and ensuring businesses can rise to the occasion. Here’s a closer look at some of the ways packaging machines are driving efficiency and keeping up with increasing consumer demand.

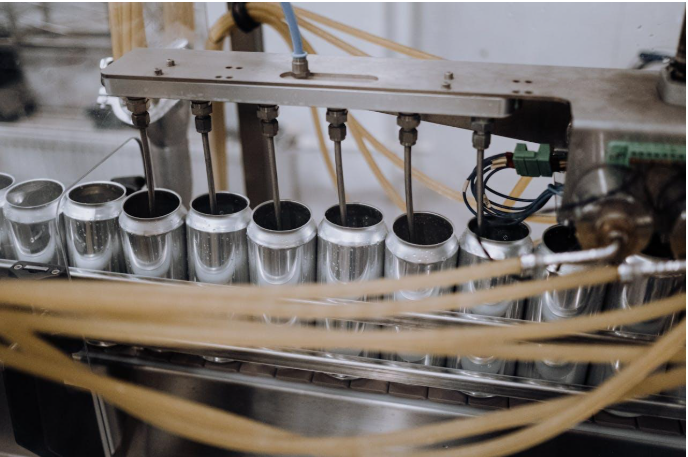

Enhanced Production Speed

When it comes to meeting high demand, speed is the name of the game. Packaging machines are engineered to handle large volumes of products at rates that are far beyond what humans alone can achieve.

Automated conveyer systems, robotic arms, and other innovations allow businesses to streamline workflows and significantly cut down on time. Continuous-flow machines, for instance, package multiple items simultaneously, ensuring that production timelines are met without unnecessary delays.

Fast doesn’t mean sloppy, either; these machines are designed to maintain accuracy and precision even under extreme speeds, enabling businesses to handle sudden spikes in demand.

Packaging Machines Help Minimizing Product Waste

If waste is eating into your profit margins, packaging machines can be a game-changer. With precise measurements and minimal human error, these machines ensure that every product is packaged with remarkable accuracy and care.

Overfilled or underfilled packages? Virtually eliminated. Damaged goods due to improper wrapping? A thing of the past. Software calibrations and smart sensors allow businesses to minimize waste not only of the products themselves but also of materials like plastic, paper, or foil used in packaging.

Reduce Labor Costs

Staffing significant production lines can be costly, especially if demand requires operating around the clock. Packaging machines relieve much of that burden by automating repetitive and time-intensive tasks.

While human expertise is still critical for oversight, maintenance, and strategy, automating the packaging process can significantly reduce the need for large labor forces. Additionally, this shift creates opportunities for businesses to reinvest in upskilling their workforce.

Employees who previously performed manual packaging tasks can be trained to manage, program, and maintain these advanced systems instead, creating a more skilled and dynamic team.

Adapt to Different Product Sizes and Shapes

The days of one-size-fits-all packaging solutions are gone. Today’s customers want variety and personalization, and businesses need to adjust to meet their needs. Packaging machines are up for the challenge.

Thanks to modular and customizable designs, these machines can easily be adjusted to accommodate a wide range of product sizes, shapes, and materials.

Whether you’re switching between snack-sized packages and family-sized containers or pivoting from square boxes to cylinder cartons, modern machines make transitioning seamless.

Improve Workplace Safety

Safety is a top priority for any business, and packaging machines play a significant role in creating a safer work environment.

Automating dangerous or repetitive tasks reduces the risk of workplace accidents and injuries, while safety features like emergency stop functions and protective barriers ensure operators remain safe during machine use.

Not only does this protect employees, but it also minimizes disruptions caused by injury-related downtime or compliance violations.